Chain Care Part 1

This information was first published in 1961 by Renold Chains. It is still relevant for those restoring and riding old motorcycles today.

INTRODUCTION

The motorcycle is designed and built for efficient and reliable performance. To give of its best, however, it calls for some attention, and no enthusiastic owner will begrudge the small amount of time spent on maintenance.

Chain drive is the established method of transmitting power from the engine, via the gearbox, to the rear wheel. It has held this position for some hundred years, during which time engine power has increased six-fold on all capacities of machines ridden on public roads.

Motorcycle chains have been consistently developed to meet the ever-increasing demands made on motorcycle transmission systems since the first all-chain-driven British motorcycle – the P and M – was offered to the public in the early 1900’s. Since then chain transmission has more than kept pace with motorcycle development. A transmission of such proven merit deserves its quota of attention to enable it to operate to the fullest advantage. This information will assist you in obtaining maximum service from your chains.

LUBRICATION

Primary chains

Every joint or “articulating point” in a chain is actually a plain bearing of steel to steel on hardened surfaces. It is essential that a film of lubrication is at all times present to prevent actual metal-to-metal contact. This film not only cuts down friction to negligible proportions, but also assists in cushioning the drive, in effect, hydraulically.

Cross section of a chain link

The oil-bath chaincase which is standard on virtually all machines, other than those specifically designed for road-racing, ensures that the high-speed primary chain is fully protected, and provides for lubrication in the most efficient manner.

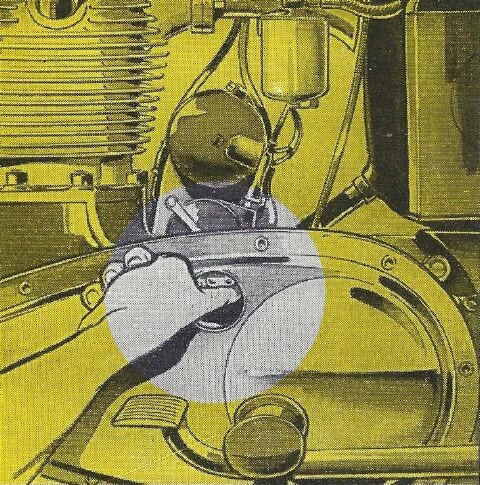

Enclosed primary chaincase

The only attention required is to check the chaincase periodically to ensure that there are no oil leaks (as from unserviceable gaskets or loosened flanged joints). External cleanliness of the case is ensured by correct assembly of packing washers and tight screws.

The oil level must be adequate to submerge the lower strand of the chain, and checked with the machine on an even keel. The oil must be changed when it becomes dirty or sludgy. Frequency of changing depends largely on the design of the clutch. If this runs in the oil, the makers may recommend draining and refilling at intervals of 1,000 miles or so. Where the clutch runs “dry” longer mileages can be run before changing.

The importance of maintaining the correct oil level in the chaincase cannot be over-emphasised. A very minor leak will allow the level to fall below the chain in quite a short time. Even though some oil may be present in the case, the chain will run dry, with the inevitable result of rapid wear of both chain and chainwheels (sprockets).

An early indication that the chain is being starved of oil is the appearance at the joints of a reddish-brown deposit, and this should be taken as a warning that there is something wrong with the lubrication.

Rear Chain

The rear driving chain nearly always runs semi-exposed, its protection comprising usually of a guard over the top run, with the addition of side valances on some machines. This drive runs, of course, at only about half of the primary chain speed, but carries a heavy bearing loading (varying according to the gear engaged), which must be catered for by adequate lubrication if excessive wear and friction are to be avoided.

Rear chainguard showing top and side protection

Many machines fit as standard a metered oil feed to the rear chain, sometimes from the primary chaincase oil supply and sometimes from the main oil tank. The feed is controllable by an adjustable valve. Once set properly, so that sufficient oil is delivered to the sideplates of the chain without an excess finding its way on to other parts of the machine, this device is generally adequate.

Adjusting the rear oil feed fed from the primary chaincase

When no such automatic lubricating device is provided, periodic hand lubrication of the chain is essential to prevent premature chain wear. For this purpose, a pressurised can of chain lube should be purchased and kept handy, and oil applied to the chain whenever it appears to be dry. The oil should be directed, primarily, at the roller and link edges to ensure as much penetration as possible to the internal working surfaces of the chain.

Periodically, the chain should be removed, washed in kerosene, and after allowing the kerosene to dry off, drenched in chain lube. The chain can then be refitted to the machine after cleaning the chainwheels (sprockets). Of course, this does not apply to o-ring chains, but o-ring chains are not normally used on old motorcycles because of the lack of side clearance between the gearbox and primary drive.

CHAIN MEASUREMENT

If all other items concerned with the power transmission are correct, too rapid a rate of chain wear is invariably caused by inadequate lubrication. It is useful to know the extent of wear, and a simple test for this consists of measuring the chain with an ordinary foot rule, preferably steel. Wear of up to ¼” per foot of chain length is accommodated by the depth of hardening of the bearing surfaces, and when this limit is reached the chain should be replaced.

Method of chain measurement

With a new 5/8” pitch chain, 16 pitches will come to the 10” mark on the rule, and a sufficiently accurate check for subsequent wear is to take a limit of 10-7/32” for 16 pitches.

In the case of a ½” pitch chain, 23 pitches will come to the 11-1/2” mark on the rule, and the limit of 11-3/4” for 23 pitches should be taken as the maximum permissible wear.

For a 3/8” pitch chain, 24 pitches of a new chain will come to the 9” mark on the rule, and the limit of 9-3/16” for 24 pitches should be taken as the maximum permissible wear for this size of chain.

Naturally, the test should be made carefully to obtain an accurate result. The chain is first washed in kerosene to ensure that all joints are free, and laid unlubricated on a flat board. If it is anchored at one end by a nail the necessary tension to pull it out to its fullest extent can be applied with one hand, while measuring between the centres of the bearing pins.

CHAIN ADJUSTMENT

A new chain takes a little time to bed down, and during this period will require adjustment. After this, oil-bath enclosed chains will run for a very long time without further attention, but exposed drives will call for more frequent adjustment, and periodical checking is necessary.

Correct adjustment is determined by the degree of up-and-down movement of the chain midway between the wheels, average figures being:

Primary chain – ½”

Rear chain – ¾” (with rigid frame)

Magneto and similar – ¼”

Measuring the slack in the top run of the chain

On spring-frame machines, the rear chain tension will vary according to the position of the suspension travel. The suspension should therefore be held in the position at which the chain is tightest, and the latter then adjusted to be just free at this point. If the manufacturer’s instruction book gives specific details regarding this adjustment, these should be adhered to. Always re-check adjustment of any chain after final tightening of nuts, etc.

Measuring the slack in the rear chain

It is preferable to leave the gearbox adjusting screws in the “hard-up” position, tending to push the gearbox forward. This will help to resist any tendency for the gearbox to “creep” backwards (and thus tighten the primary chain) due to rear chain pull.

Method of adjusting the chain tension

Continue reading on Chain Care part 2…